About the HEATSTACK project

The HEATSTACK project represents a key step towards achieving commercial cost targets for fuel cell mCHP appliances, bringing together leading technology providers in the fuel cell mCHP supply chain with extensive industrial expertise to accelerate the development towards volume production of the fuel cell stacks and heat exchangers. Cost reductions will be achieved through advanced design, development and industrialisation of core manufacturing processes. Improvements to component performance with advanced materials will reduce system degradation and improve overall system efficiency and lifetime.

Objectives

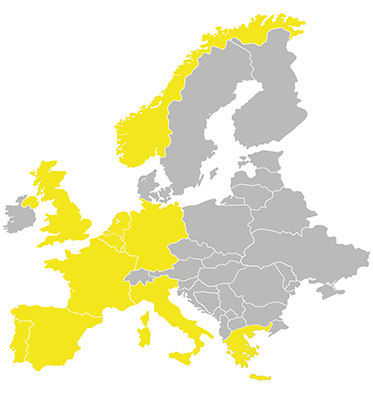

The HEATSTACK project will deliver a production-ready CAPH design and process, and a production line for the SOC stack glass seals including glass-paste and electrical insulating layers. This will represent a crucial step towards achieving cost reductions of more than 50% for these two key SOFC mCHP system components. Through this, HEATSTACK will have a huge impact on the overall fuel cell system costs. Further cost improvements of main components (e.g. Insulation, Reformer, Fan) as well as a volume effect generated from this project and other FCH JU initiatives under the Horizon 2020 programme, are the main drivers for achieving commercial cost targets. Through the establishment of the mass market in Europe (100.000 unit sales for per annum), a reduction of 80% is targeted.