The EU-funded Horizon 2020 project PLATIRUS (PLATInum group metals Recovery Using Secondary raw materials) presented its research results at a final online exploitation workshop on 21 April 2021. The online event #ExploitPLATIRUS marked the culmination of four years and six months of practice-orientated research and full-scale sustainable demonstrations on 11 recycling platinum group metals (PGMs) technologies through 3 main phases: leaching, separation and recovery.

PLATIRUS results

The project results are joint efforts of 11 project partners from Europe who represent the whole market value chain:

- Eleven innovative, cost-efficient and sustainable technologies developed by VITO, SINTEF, Vienna University of Technology, TECNALIA and KU Leuven have succeeded to recover PGMs from spent autocatalysts, mining and electronic waste, and demonstrated it is possible to use the recycled PGMs to manufacture brand new autocatalysts with very high performances meeting the automotive standards.

- Among the 11 PLATIRUS technologies, 3 of them have exceled due to their high efficiency and recovery rate, low cost, sustainability and low environmental impact, and have been scaled up to TRL5 and are now ready for further scale up for industrial use.

-

- Microwave (MW) assisted leaching developed by VITO,

- Non-conventional liquid-liquid separation developed by KU Leuven,

- Gas-diffusion electrocrystallization (GDEx) developed by VITO.

- The economic viability of the PLATIRUS technologies has demonstrated a payback period of around 6 years in conservative scenarios, and an accumulated revenue of almost 4 times the initial investment that would be reached in the 15th year of production.

- Six PLATIRUS technologies were awarded by the European Commission as Great EU innovations. The project partners SINTEF, VITO, KU Leuven have received the Innovation Radar Prize in 2018 and 2020 for their development of breakthrough solutions to recycle PGMs from secondary waste sources.

- One patent of the Gas-diffusion electrocrystallization (GDEx) technology for Pd recovery; cementation of Pt recovery and precipitation for Rh recovery developed by VITO has been granted.

Workshop outcome

During the final online exploitation workshop, the PLATIRUS consortium showcased the key outcomes of their years-long research on the advancement on the technical and scientific levels for the novel recycling technologies proposed as well as on the financial, economic, environmental and market impact of those technologies. More than 80 participants from the waste treatment, processing, refining sectors and end-users attended the seminar.

The final workshop featured presentations by 19 key speakers from TECNALIA, Monolithos, KU Leuven, Vienna University of Technology, VITO, SINTEF, CRF, Ford Otosan, Boliden Harjavalta Oy, Johnson Matthey and PNO Innovation Belgium. Additionally, a representative of the European Commission (EC) presented insights about the EC vision on supporting critical raw materials related activities in the new research programme Horizon Europe.

In the end of the workshop it was announced that 2 of the selected recovery and refining technologies developed to TRL 5 in the PLATIRUS project MW assisted leching and GDEx will be scaled up further to TRL 7 in a new EU-funded Horizon 2020 project PEACOC: Pre-commercial pilot for the efficient recovery of Precious Metals from European end-of-life resources with novel low-cost technologies.

PEACOC project

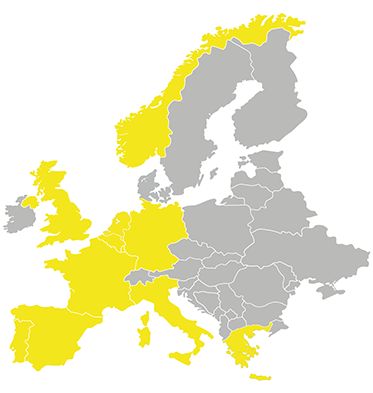

The key objective of the PEACOC project is to demonstrate on a pre-commercial pilot scale at TRL 7, a novel, economically and environmentally viable metallurgical process for the recovery of precious metals from a wide variety of end-of-life products that are abundantly available in Europe. The project consortium has 19 partners from 10 European countries and Turkey that represents the whole industrial value chain. The project will be coordinated by TECNALIA and will run for 4 years starting May 2021.

Find out more about the final PLATIRUS results and outcomes in the final project newsletter #8.

The PLATIRUS consortium.

*As of April 2020, Env-Aqua Solutions is not part of the PLATIRUS consortium.