Project title: Recycling of high-quality secondary thermoplastics and recovery of critical raw materials (antimony) from mixed plastic waste in the automotive and the electrical and electronic equipment sectors.

Funding programme: LIFE Programme

Duration: 01/07/2019 – 30/12/2022

Overview of the LIFE PlasPLUS project

LIFE PlasPLUS is a project funded under the European Union’s LIFE programme for Environment and Resource Efficiency. The project targets an innovative technology challenging the current state-of-the-art recycling process and transforming the current downcycled or landfilled/incinerated waste in high-purity secondary thermoplastics.

LIFE PlasPLUS improves the recycling of high-quality secondary thermoplastics and critical raw materials found in end-of-life vehicle waste (ELV) and waste of the electrical and electronic equipment (WEEE). The three major project objectives are :

- Step 1: Production of high purity thermoplastics

- Step 2: Automated multi-class sensor-based sorting and separation of Flame Retardant Plastics

- Step 3: Recycling of by-product Antimony (Sb) through catalytic conversion and hydrometallurgy

Furthermore, LIFE PlasPLUS seeks to provide a complete solution for the economic recovery of thermoplastics and by-products through transformation in added-value raw materials and products for the automotive and electrical and electronic equipment sectors.

By using secondary thermoplastics instead of virgin material, the fast-growing sectors will limit energy, water, and resource consumption, as well as cut gas emissions while reusing critical raw materials.

Project objectives

- Demonstrate the feasibility of recycling 45% of the plastic concentrate into added-value thermoplastic streams by scaling up a new froth flotation/triboelectricity demonstration unit.

- Achieve a scale up of the current prototype from batch production of 150 kg/h with technology readiness level (TRL)6 to pre-commercial level of continuous production at 1 500 kg/h at TRL7. This will process >98%-pure polystyrene (PP), filled polypropylene (FPP) and acrylonitrile butadiene styrene (ABS) regrinds.

- Adapt a sensor-enabled separator that can detect flame retardant plastics (FRPs) [250 kg/h throughput] and separate fibre-reinforced plastic at 250 kg/h.

- Substitute >40% virgin thermoplastics with secondary ones in three new secondary compounds for the automotive and EEE markets;

- Validate the quality of the produced compounds in three standard vehicle parts and in flame retardant batches for the EEE sector.

- Showcase a closed-loop production for the valuable flame-retardant element (Antimony Trioxide -ATO- or Sb2O3), also validating its flame-retardant performance in recycled plastics.

- Conduct life cycle analyses and socio-economic analyses to confirm the environmental benefits and techno-economic soundness of the concept.

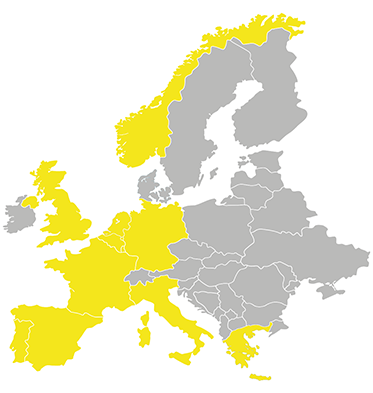

- Develop a replication and transfer plan as a sustainable business model for other facilities around Europe.